Automotive Timing Belts are indispensable parts of automotive engines. These belts synthesize the respective advantages of conventional belt, chain and gear drives. The power transmission is via the mesh between belt teeth and belt pulley. They are mainly used for automatic overhead camp shaft drives and can meet the working requirement of variable speed and high temperature.

Features

- Solves potential problems caused by using a conventional metal chain such as :

~No decrease in horsepower at high-speed

~Easily designed to span the distance between the drive pulleys and maintain constant tension.

- Prevents belt elasticity by using glass fibers for the tension member.

- Excellent in resistance against heat, oil and wear.

- Guarantees high-power transmission efficiency under driving conditions of

high-speed and severe temperature fluctuation. - Shows stable performance at high-speed rotation.

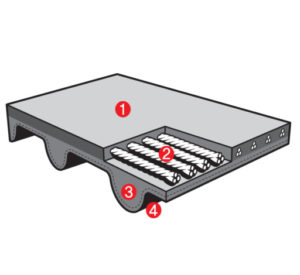

| Construction | Functions | Materials |

|---|---|---|

| 1 Rear Rubber | Protects tension member | CR, HNBR |

| 2 Tension member | Primary material for transferring power | Glass Fiber |

| 3 Teeth rubber | Protects tension member, maintains belt shape | CR, HNBR |

| 4 Bottom fabric | Maintains belt and teeth shape | Nylon |

| CR : Chloroprene Rubber / EPDM : Ethylene Propylene Diene Monomer | ||

Products and Specifications

Click ‘Inquire Now’ to send us your requirement

| Type | Pb(mm) | Ht(mm) | Hs(mm) | |

|---|---|---|---|---|

| ZA | 9.525 | 1.91 | 4.1 | Inquire Now! |

| ZB | 9.525 | 2.29 | 4.5 | Inquire Now! |